There are standard ranges for refrigeration as well as freezing for drug substances in biologics logistics. Logistic partners have to be able to take care of the products across these ranges with flexibility underpinned by strong SOPs. Controls when it comes to humidity as well as temperature throughout storage and transport must be given due consideration.

They ought to be monitored in real-time with risk management systems as well as continuity plans in place in case there is a failure in control. Tracking and monitoring the tech is crucial to making sure of high fidelity when it comes to temperature data during transit so as to help with decision-making throughout every level of the supply chain.

Market growth for the worldwide specialty drug distribution sector

Growing at a CAGR of 14.2% since last year, the global specialty drug distribution market is anticipated to reach a figure of $6 billion by 2031.

This is going to be partly driven due to the elevation in development as well as the manufacturing of new vaccines, cells, and gene therapies- CGTs.

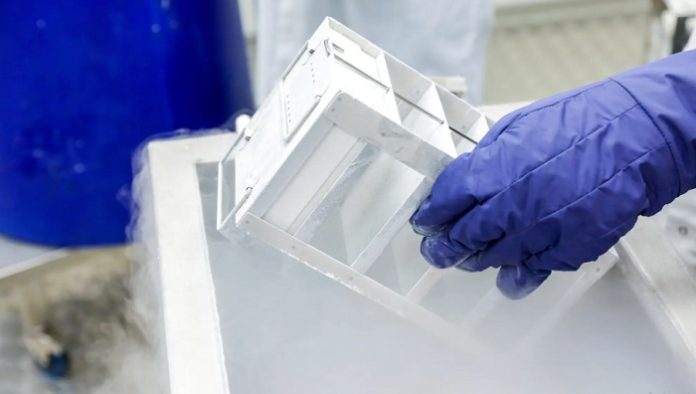

It is well to be noted that CGTs happen to be promising innovative therapeutics that help in treating chronic diseases, but they also require cryogenic storage to maintain their stability. Apparently, patient-centric CGTs also add more complexity because of their need for temp-controlled transport so as to collect patient cells, develop the CGT, and thereafter administer the same to the patient.

This happens to result in cold storage facilities, tight shipping windows, packaging tech that’s thermally controlled, and strict requirements of regulation in order to satisfy the needs of manufacturers and also patients.

So as to help overcome these issues, companies often turn to third-party logistics suppliers. Due to the robust SOPs, the 3PLs go on to provide solutions when it comes to cold-chain logistics so as to make sure of a temperature-controlled delivery of a drug substance that is efficient.

A strategy that’s devised early

It’s crucial to plan and also execute a cold chain supply strategy when it comes to early product development, most ideally between IIb and III, so as to get rid of errors as well as delays. Although a product may find it difficult to make it to the market, this proactive approach goes on to identify and lessen problems so that the therapy is likely to reach its destination rapidly once it gets approved.

This also enables in eradicating the excursion event risk when a time- and temperature-sensitive pharmaceutical product happens to be outside of a set time or range.

That said, even when calculating all the possible risks, certain circumstances that are unforeseen can still lead to temperature variations between shipments. But how can one know if this occurs, and what can be done so that it does not happen again?

Monitoring in real-time

The storage and handling conditions that are required are gauged based on the data pertaining to product stability. As a variation can even go on to impact the efficacy as well as safety of the drug, making sure that these product conditions are stored all across shipping as well as its delivery happens to be crucial.

When in case utilising the temperature monitors in the past, the only way it would have been known that the temperature variations had taken place was after the delivery, when the temperature monitor would be read out. Based on if the temperature monitor was provided by the logistics handler, it would take hours or even days to assess if the temperature variation had taken place.

During all that process, the product had to be kept on hold, thereby wasting valuable time. It is well worth noting that including sensors with the shipments can help with the real-time monitoring of delivery conditions right from location and humidity to light exposure to shock and temperature. Because of the help of accurate tracking, any event of variation, regardless of its size, would get recorded and reported to the shipper as well as the logistics partner.

This data then goes through careful assessment so as to make sure that the product is safe for use.

Real-time tracking also helps in response that’s fast. For instance, tracking the shipment path makes sure that the product location and the delivery track are on the same path. If a deviation gets reported, executing a continuity plan or coming up with a new strategy through direct contact with the shipment would aim to get hold of a tight timeline. Data collection across the delivery timeline by the logistics partner helps the pharmaceutical company verify the product’s validity before administering it to the patient. This data happens to be invaluable when it comes to decision-making across the client timeline.

Taking the right measures

The tracking data that gets collected happens to have great value when it comes to making informed decisions at each stage of a company’s supply chain that is both time- and temperature-sensitive. Corrective measures could be taken so as to re-establish the initial conditions if an excursion event has occurred. That said, there is a patient waiting at the other end of the supply chain, and lives are at stake; hence, any recorded discrepancies have to be looked into right before the drug reaches the hands of the patient, even in case the product conditions happen to be rapidly re-established.

When subject to a temperature variation event, the decision tree made by the collected data, stability testing information, and optimised distribution strategy can be used in terms of determining whether to release the drug batch or not. The drug will either be deemed safe or useless.

Consistent enhancement and analysis

Besides the real-time monitoring, all the data that’s collected can be analysed so as to highlight problems that are recurring or areas for improvement. For instance, if there is one route that is often leading to more delays because of traffic, an alternative route could be opted for, or if a specific packaging choice leads to more variations in statistics, then an alternate packaging option can be looked into.

This continuous enhancement can aid in building a stronger strategy and also lessen the risk associated with the cold-chain supply.

Conclusion

Variations can go on to occur anywhere during the production and distribution timelines. As manufacturers must stick to good manufacturing practises as well as good distribution practises, recording any variations across this timeline is very critical.

Having a logistics partner who has robust temperature-controlled handling capabilities as well as transportation capabilities and a clear product-customised strategy is crucial for effective and safe distribution, which ultimately leads to the continuity of business. Teamed with precise tech so as to monitor excursions, a safe as well as efficacious product can be rolled out to its destination, ready for administration to patients, thereby helping to create healthier outcomes.