The pharmaceutical and biotechnology industries are experiencing a profound technological revolution driven by CRISPR-Cas9 and emerging gene editing technologies that fundamentally alter how therapeutic agents are developed and manufactured. Gene editing pharma manufacturing represents far more than incremental improvement in existing bioprocessing approaches; it signifies a paradigm shift in how scientists engineer cellular systems, control biological processes, and manufacture complex therapeutics at commercial scale. The global CRISPR-based gene editing market, valued at USD 4.46 billion in 2025, is projected to reach approximately USD 13.39 billion by 2034, reflecting the explosive growth of applications spanning drug discovery, cell therapy, and manufacturing optimization.

CRISPR technology has enabled unprecedented capabilities in cell line engineering, allowing pharmaceutical manufacturers to design producer cells with precisely tailored characteristics that enhance productivity, improve product quality, and reduce manufacturing complexity. Unlike earlier gene editing tools that were slow, expensive, and imprecise, CRISPR-Cas9 systems achieve rapid, cost-effective, and remarkably accurate genome modifications. This technological breakthrough is reshaping bioprocessing strategies across multiple domains: enabling CAR-T cell optimization for cancer therapies, engineering mammalian cell lines for improved protein expression, creating more efficient viral vector production systems, and developing next-generation therapeutic platforms. The integration of CRISPR technology with artificial intelligence and automated bioprocessing systems is creating synergies that multiply the impact of individual technologies.

CRISPR’s Impact on Cell Line Development and Bioprocess Engineering

Revolutionary Cell Line Engineering Capabilities

Traditional cell line development relied primarily on screening vast libraries of randomly mutagenized cells to identify rare clones exhibiting superior productivity or desired characteristics. This empirical approach was inherently inefficient, requiring months of laborious work to establish stable producer cell lines while maintaining detailed phenotypic characterization. CRISPR technology has inverted this paradigm, enabling rational cell line design where scientists directly engineer specific genetic modifications to achieve predetermined characteristics. The transition from trial-and-error screening to engineered cell lines compressed development timelines from six months to approximately three weeks while dramatically improving outcome predictability and manufacturing performance.

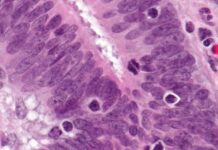

Chinese Hamster Ovary (CHO) cells remain the industry standard for recombinant protein production, and CRISPR-based engineering is unlocking new capabilities for these crucial producer systems. Targeted knockouts of problematic host cell proteins, optimization of glycosylation patterns to match human-like profiles, and enhancement of cellular stress tolerance now represent routine applications of CRISPR technology. By engineering specific knockout phenotypes, researchers have demonstrated that CRISPR-modified CHO cells vastly outperform conventionally selected clones, achieving higher viabilities under bioreactor stress conditions while maintaining consistent product quality throughout extended culture periods. Enhanced expression of anti-apoptotic genes such as Bcl-2 and Bcl-xL through CRISPR-mediated modification has proven particularly valuable, extending culture longevity, improving cell viability, and enabling higher yields of therapeutic proteins with significant economic advantages for biopharmaceutical manufacturers.

Gene Therapy and Viral Vector Manufacturing Optimization

Gene therapy manufacturing presents unique scaling challenges that CRISPR technology is helping to address. Unlike traditional biopharmaceuticals where the protein product is independent of production system modifications, gene therapy requires maintaining precise control over transfection efficiency, viral vector titer, and product safety. CRISPR-based approaches enable engineer of producer cell lines that express optimized transfection machinery, improving the efficiency with which therapeutic genes are packaged into viral vectors. For recombinant adeno-associated virus (rAAV) production, CRISPR-engineered cells demonstrate significantly enhanced productivity while maintaining consistent product quality across manufacturing scales.

The Luxturna case study exemplifies CRISPR’s influence on gene therapy manufacturing. By engineering cell lines specifically optimized for AAV production, manufacturers have achieved more consistent titers and improved production efficiency compared to earlier-generation systems. These advances are particularly critical for rare disease indications like Leber congenital amaurosis where limited patient populations demand highly efficient manufacturing to maintain economic viability. CRISPR-engineered producer systems enable scale-out strategies that maintain process consistency and product quality while expanding production capacity to serve growing patient populations.

AI Integration and Intelligent Bioprocessing Control

Machine Learning Enhancement of Gene Editing Efficacy

The convergence of artificial intelligence with CRISPR technology creates powerful capabilities for optimizing gene editing outcomes while minimizing off-target modifications that could compromise cell viability or therapeutic efficacy. Machine learning algorithms trained on extensive CRISPR dataset now predict the most effective guide RNA sequences for specific genomic targets, reducing off-target editing risks through computational analysis of potential alternative binding sites. AI models also predict optimal editing conditions—temperature, timing, and chemical environments—that maximize on-target modifications while minimizing cellular damage.

Automated robotic platforms integrated with AI-driven protocols now perform hundreds of CRISPR gene editing experiments simultaneously, dramatically accelerating cell line development while maintaining unprecedented consistency. These high-throughput, AI-enhanced systems identify optimal editing targets, predict phenotypic outcomes from specific genetic modifications, and recommend manufacturing process parameters based on cell line characteristics. The combination of CRISPR precision with AI-driven optimization represents the next generation of rational bioprocess design, where manufacturing processes are engineered from first principles rather than discovered through extensive empirical experimentation.

Real-Time Process Control and Quality Assurance

CRISPR-engineered producer cells often exhibit distinct metabolic characteristics and quality attribute profiles that require tailored process control strategies. Artificial intelligence systems analyzing real-time bioprocess data can now dynamically adjust culture conditions—pH, temperature, nutrient feeding strategies, oxygen transfer rates—based on continuous monitoring of CRISPR-modified cell performance. These adaptive control systems maintain optimal conditions throughout production campaigns, improving yields, reducing process variability, and ensuring consistent product quality.

Quality assurance for CRISPR-modified therapeutics involves novel considerations regarding potential off-target genetic modifications and long-term stability of engineered phenotypes. Advanced sequencing techniques coupled with AI analysis can comprehensively verify that therapeutic products result exclusively from intended CRISPR modifications without undesired genetic alterations. These quality assurance methodologies provide regulators with confidence that CRISPR-manufactured products maintain consistent specifications across commercial manufacturing campaigns.

CRISPR Applications Across Pharmaceutical Manufacturing

| Application Area | Current Use | Bioprocess Advantage | Example Targets |

| Cell Line Engineering | CHO cell optimization | 50% productivity increase | Glycosylation, protein yield |

| Gene Therapy Production | AAV vector manufacturing | Improved transfection efficiency | Luxturna, similar AAV therapies |

| CAR-T Manufacturing | T-cell engineering | Enhanced CAR specificity, reduced off-targets | Oncology indications |

| Quality Improvement | Host cell protein reduction | Simpler downstream processing | Adventitious agents removal |

| Viral Vector Systems | Production cell optimization | Higher viral titer, consistency | Multiple AAV serotypes |

| Metabolic Engineering | Nutrient efficiency | Reduced culture media costs | Media component optimization |

Regulatory Framework Evolution and Manufacturing Implications

The revolutionary speed of CRISPR adoption has outpaced regulatory guidance development, creating uncertainty regarding validation requirements, quality control expectations, and long-term safety considerations for CRISPR-manufactured therapeutics. Forward-thinking regulatory agencies are developing frameworks that recognize CRISPR’s unique characteristics while maintaining commitment to patient safety. The FDA’s approval of CASGEVY (exagamglogene autotemcel) for sickle cell disease in November 2023 marked a historic milestone as the world’s first CRISPR gene-editing therapy available to patients, establishing important precedents for regulatory pathways supporting CRISPR-derived therapeutics.

Pharmaceutical manufacturers must implement comprehensive characterization programs verifying that CRISPR-modified cell lines maintain stability across multiple passages, produce consistent product quality, and demonstrate predictable performance under manufacturing stress conditions. Whole genome sequencing of CRISPR-engineered cells has become standard practice, providing regulators with detailed documentation that editing occurred precisely at intended genomic locations without unintended modifications affecting cell viability or product quality. These rigorous characterization approaches, while requiring initial investment, ultimately strengthen regulatory confidence and support faster approval timelines for CRISPR-derived therapeutics.

Advanced Applications and Future Innovations

Multiplexed Gene Editing and Synthetic Cell Engineering

The capability to simultaneously modify multiple genomic targets through multiplexed CRISPR approaches enables creation of producer cells engineered for simultaneous optimization across numerous characteristics. Researchers are now designing CHO cells with coordinated modifications to glycosylation enzymes, anti-apoptotic factors, nutrient uptake systems, and waste product clearance pathways. These comprehensively engineered cells demonstrate superior performance compared to cells modified for single characteristics, highlighting the power of systems-level optimization enabled by CRISPR technology.

Emerging synthetic biology approaches are enabling even more sophisticated cell engineering where CRISPR technology incorporates entirely novel genetic circuits into producer cells. These synthetic circuits enable precise control over protein expression timing, metabolic pathway activation, and stress response mechanisms. The resulting “smart cells” can autonomously adjust their behavior to maintain optimal manufacturing conditions, adapting to changes in nutrient availability, oxygen supply, or waste accumulation with minimal external intervention.

Integration with Digital Manufacturing and Quantum Computing

The combination of CRISPR-engineered cells with digital twin technologies and quantum computing represents the frontier of next-generation pharmaceutical manufacturing. Digital twins of CRISPR-modified production systems can simulate how genetic modifications affect bioprocess dynamics, predict quality outcomes under varying manufacturing conditions, and optimize process parameters without requiring extensive physical experimentation. Quantum computing systems promise to accelerate molecular modeling of CRISPR-target interactions, guide RNA design optimization, and prediction of off-target binding events with unprecedented accuracy.

Gene editing pharmaceutical manufacturing stands at an inflection point where CRISPR technology has matured from research tool to practical manufacturing platform. The convergence of gene editing, artificial intelligence, automation, and digital technologies is creating next-generation bioprocessing systems capable of unprecedented efficiency, consistency, and product quality. Organizations that successfully integrate CRISPR engineering with sophisticated process control and quality assurance methodologies will establish enduring competitive advantages in increasingly complex biopharmaceutical markets.