Revolutionizing Cold Chain Management Through Artificial Intelligence

The pharmaceutical industry stands at the threshold of a transformative era where artificial intelligence and predictive analytics are fundamentally reshaping cold chain risk management strategies. The integration of AI technologies has evolved from experimental implementations to essential operational capabilities that enable proactive decision-making, optimize supply chain efficiency, and ensure the integrity of temperature-sensitive pharmaceutical products throughout their journey from manufacturing to patient administration .

The complexity of modern pharmaceutical supply chains, combined with the increasing prevalence of biologics and temperature-sensitive medications, has created an environment where traditional reactive management approaches are insufficient to meet the demands for reliability, efficiency, and compliance. AI-driven systems provide the analytical capabilities necessary to process vast amounts of data from multiple sources, identify patterns and trends that human operators might miss, and generate actionable insights that prevent problems before they impact product quality or patient safety .

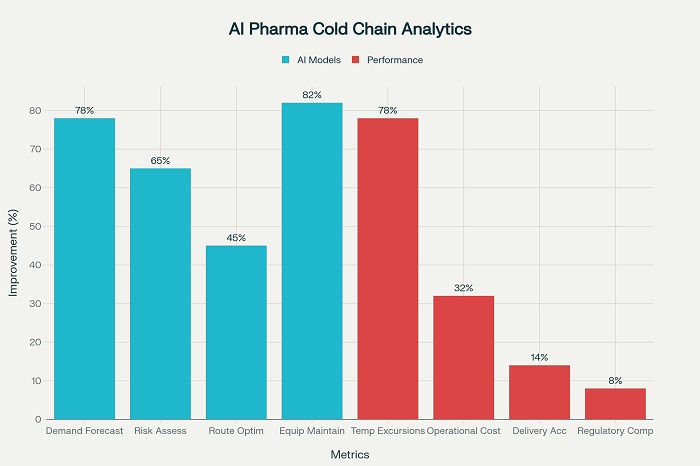

Recent developments in machine learning and predictive analytics have demonstrated remarkable success in pharmaceutical cold chain applications, with companies reporting reductions of up to 78% in temperature excursions and significant improvements in operational efficiency through AI-powered optimization systems . These achievements underscore the transformative potential of AI technologies in creating more resilient and responsive cold chain operations.

Predictive Analytics for Demand Forecasting and Inventory Optimization

AI-powered predictive analytics systems analyze historical data, market trends, seasonal variations, and external factors to generate highly accurate demand forecasts that enable pharmaceutical companies to optimize inventory levels and reduce waste while ensuring product availability. These sophisticated forecasting models can incorporate diverse data sources, including electronic health records, social media trends, and epidemiological data, to predict demand patterns with unprecedented accuracy .

The integration of machine learning algorithms enables continuous improvement of forecasting accuracy as systems learn from new data and adapt to changing market conditions. This adaptive capability is particularly valuable in the pharmaceutical industry, where demand patterns can be influenced by factors such as disease outbreaks, regulatory changes, and competitive dynamics that may not be apparent in historical data alone .

Dynamic Inventory Management and Optimization

AI-driven inventory management systems optimize stock levels across the entire supply chain network, taking into account factors such as product shelf life, storage costs, transportation constraints, and demand variability. These systems can automatically adjust inventory parameters based on real-time conditions and predictive insights, ensuring optimal balance between product availability and cost efficiency .

Advanced algorithms consider the unique characteristics of pharmaceutical products, including expiration dates, temperature requirements, and regulatory constraints, to develop inventory strategies that minimize waste while maintaining high service levels. This optimization is particularly critical for expensive biologics and vaccines that have limited shelf life and require continuous cold chain maintenance.

Scenario Planning and Risk Assessment

AI systems enable sophisticated scenario planning capabilities that simulate various disruption scenarios and assess their potential impact on supply chain operations. These simulations can model the effects of events such as equipment failures, transportation delays, extreme weather conditions, and sudden demand spikes, enabling organizations to develop robust contingency plans .

The scenario planning capabilities extend to regulatory changes, geopolitical events, and market dynamics that could affect pharmaceutical supply chains. By modeling these scenarios, organizations can proactively develop mitigation strategies and ensure business continuity under various challenging conditions.

Real-Time Risk Detection and Automated Response Systems

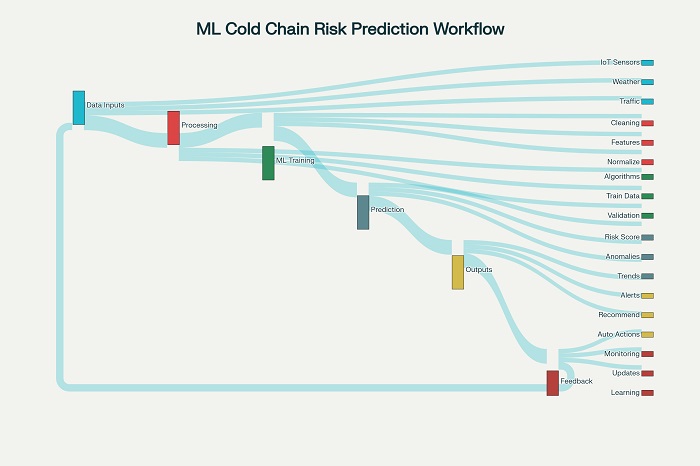

Machine learning algorithms continuously analyze data from IoT sensors, transportation systems, and environmental monitoring equipment to identify patterns that indicate potential risks to cold chain integrity. These systems can detect subtle changes in equipment performance, environmental conditions, or operational patterns that may precede more serious problems, enabling proactive intervention before product quality is compromised .

Real-time risk detection systems incorporate multiple data sources to provide comprehensive situational awareness, including temperature and humidity sensors, GPS tracking data, weather forecasts, and traffic information. The integration of these diverse data streams enables identification of complex risk scenarios that might not be apparent when examining individual data sources separately .

Automated Alert Generation and Escalation Procedures

AI-powered alert systems generate intelligent notifications that prioritize risks based on potential impact, urgency, and available response options. These systems can differentiate between routine operational variations and serious threats to product integrity, reducing alert fatigue while ensuring that critical situations receive immediate attention .

Automated escalation procedures ensure that appropriate personnel are notified based on the severity and nature of detected risks. The systems can adapt notification protocols based on personnel availability, expertise requirements, and organizational hierarchy, ensuring rapid response to critical situations regardless of time or circumstances.

Predictive Maintenance and Equipment Optimization

Machine learning algorithms analyze equipment performance data to predict maintenance requirements and identify potential failures before they occur. This predictive maintenance capability is particularly valuable for cold chain operations, where equipment failures can result in significant product losses and compromise patient safety .

The predictive maintenance systems consider factors such as equipment age, usage patterns, environmental conditions, and historical performance data to optimize maintenance schedules and replacement strategies. This approach reduces unplanned downtime while minimizing maintenance costs and extending equipment life.

Route Optimization and Transportation Intelligence

AI-driven route optimization systems process real-time data from multiple sources, including traffic conditions, weather forecasts, fuel costs, and delivery constraints, to determine optimal transportation routes and schedules. These systems can dynamically adjust routes based on changing conditions, ensuring timely delivery while minimizing costs and risks to product integrity .

Advanced routing algorithms consider the specific requirements of pharmaceutical products, including temperature sensitivity, delivery time windows, and handling requirements, to develop transportation plans that maximize efficiency while maintaining product quality. The systems can also optimize vehicle loading patterns and delivery sequences to minimize temperature exposure during stops and transfers.

Dynamic Rerouting and Contingency Management

Real-time route optimization capabilities enable dynamic rerouting when unexpected conditions arise, such as traffic delays, weather events, or equipment failures. AI systems can rapidly evaluate alternative routes and transportation options, considering factors such as delivery urgency, cost implications, and risk factors to determine optimal responses .

Contingency management systems can automatically implement backup plans when primary transportation options become unavailable, ensuring continuity of cold chain operations even under challenging circumstances. These capabilities are essential for maintaining product integrity and meeting delivery commitments in dynamic operational environments.

Multi-Modal Transportation Coordination

AI systems optimize complex multi-modal transportation networks that combine road, air, sea, and rail transport modes to achieve optimal balance between cost, speed, and reliability. The systems consider the unique characteristics and constraints of each transportation mode while maintaining end-to-end cold chain integrity .

Coordination algorithms manage handoffs between different transportation modes, minimizing exposure times and ensuring seamless temperature control throughout complex logistics operations. This capability is particularly important for global pharmaceutical distribution networks that must navigate diverse transportation infrastructures and regulatory environments.

Quality Control and Compliance Automation

AI-powered quality control systems analyze vast amounts of data from manufacturing processes, storage operations, and transportation activities to identify potential quality issues before they affect product safety or efficacy. These systems can detect subtle patterns that indicate process deviations, equipment malfunctions, or environmental conditions that could compromise product quality .

Automated compliance monitoring systems ensure adherence to regulatory requirements throughout the cold chain by continuously comparing actual operations against established standards and procedures. The systems can generate compliance reports, identify deviation trends, and recommend corrective actions to maintain regulatory compliance and operational excellence.

Automated Documentation and Audit Trail Generation

AI systems automate the generation of compliance documentation and audit trails required for regulatory submissions and inspections. These systems ensure consistency and accuracy in regulatory reporting while reducing the manual effort required to maintain comprehensive documentation .

The automated documentation capabilities include generation of temperature reports, deviation investigations, and corrective action summaries that meet various regulatory requirements. This automation reduces compliance burden while ensuring that all necessary documentation is available for regulatory reviews and inspections.

Regulatory Change Management and Adaptation

AI systems monitor regulatory changes and automatically update operational procedures and compliance requirements to ensure continued adherence to evolving standards. This capability is particularly valuable in the pharmaceutical industry, where regulatory requirements frequently change and vary across different jurisdictions .

Change management systems can assess the impact of regulatory modifications on existing operations and recommend necessary adjustments to maintain compliance. This proactive approach helps organizations avoid compliance violations and maintain operational efficiency despite changing regulatory landscapes.

Integration with IoT and Sensor Networks

The convergence of AI technologies with IoT sensor networks creates powerful monitoring and control systems that provide unprecedented visibility and control over pharmaceutical cold chains. AI algorithms process data from thousands of sensors to generate comprehensive situational awareness and enable intelligent decision-making throughout the supply chain .

Integration capabilities enable AI systems to automatically adjust operational parameters based on sensor data, such as modifying refrigeration settings, adjusting transportation routes, or triggering emergency procedures when sensor readings indicate potential problems. This integration creates responsive systems that can adapt to changing conditions without human intervention.

Edge Computing and Real-Time Processing

Edge computing capabilities enable AI processing to occur at or near sensor locations, reducing latency and enabling faster response times to critical situations. This distributed processing approach is particularly valuable for time-sensitive pharmaceutical operations where rapid response to temperature excursions or other problems is essential .

Real-time processing capabilities enable immediate analysis of sensor data and generation of actionable insights without the delays associated with cloud-based processing. This capability is critical for applications where seconds or minutes can determine whether valuable pharmaceutical products are salvageable or must be discarded.

Advanced Analytics and Continuous Improvement

AI systems provide sophisticated analytics capabilities that identify improvement opportunities and optimize cold chain operations based on historical performance data and predictive insights. These analytics enable organizations to continuously refine their operations and achieve higher levels of efficiency, reliability, and compliance .

Advanced analytics capabilities include identification of performance trends, root cause analysis of problems, and recommendation of process improvements that can enhance overall system performance. The systems can analyze complex relationships between multiple variables to identify optimization opportunities that might not be apparent through traditional analysis methods.

Performance Benchmarking and KPI Optimization

AI-powered performance monitoring systems establish benchmarks for key performance indicators and continuously monitor operations against these standards. The systems can identify deviations from optimal performance and recommend corrective actions to maintain high operational standards .

Key performance indicators optimized through AI include temperature compliance rates, on-time delivery performance, cost efficiency metrics, and quality measures. The systems provide detailed analysis of performance trends and identify specific areas where improvements can be achieved.

Predictive Quality Assessment

Machine learning algorithms analyze historical data to predict product quality outcomes based on environmental exposure conditions and handling events throughout the supply chain. These predictive capabilities enable proactive quality management and support informed decisions regarding product release and disposition .

Predictive quality assessment considers factors such as temperature exposure duration, humidity conditions, vibration levels, and handling events to estimate the likelihood of quality issues before products reach their destination. This capability enables early intervention to prevent quality problems and reduces the risk of distributing compromised products.

The integration of AI and predictive analytics in pharmaceutical cold chain risk management represents a fundamental shift from reactive problem-solving to proactive optimization and prevention. Organizations that embrace these technologies will achieve significant advantages in operational efficiency, regulatory compliance, and patient safety while positioning themselves for success in an increasingly complex and demanding pharmaceutical marketplace. The continued evolution of AI capabilities promises even greater benefits in the future, making these investments essential for maintaining competitive advantage and meeting the growing demands for safe and effective pharmaceutical products.