Sustainable Fluid Management in Pharma: Reducing Energy & Resource Waste

The pharmaceutical industry stands at a critical juncture where environmental stewardship and operational excellence must converge to create truly sustainable manufacturing practices. As global awareness of environmental challenges intensifies and regulatory pressures mount, pharmaceutical companies are discovering that sustainable pharma fluid management represents not just an ethical imperative but a strategic advantage that drives innovation, reduces costs, and enhances competitive positioning.

The transformation toward sustainable pharmaceutical manufacturing has accelerated dramatically in recent years, driven by a confluence of factors including regulatory requirements, investor expectations, supply chain resilience concerns, and growing recognition that environmental sustainability and business success are inherently linked. Companies that embrace comprehensive sustainability strategies are finding that these initiatives often deliver immediate operational benefits while positioning them for long-term success in an increasingly environmentally conscious marketplace.

Comprehensive Water Conservation Strategies

Water represents one of the most critical resources in pharmaceutical manufacturing, with traditional production processes consuming enormous quantities for cleaning, cooling, steam generation, and direct product incorporation. The implementation of advanced water conservation pharma technologies has become essential for sustainable operations, with leading manufacturers achieving dramatic reductions in water consumption through innovative approaches to water management and reuse.

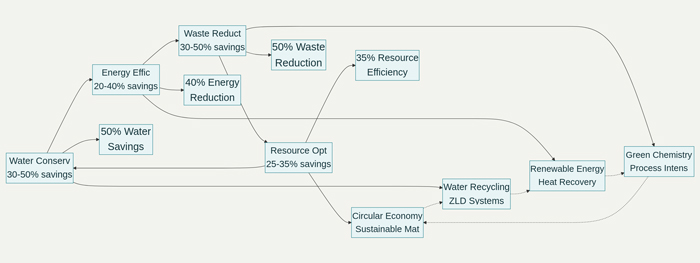

Advanced water treatment and recycling systems enable pharmaceutical facilities to dramatically reduce freshwater consumption by treating and reusing wastewater streams. Modern treatment technologies, including reverse osmosis, ultrafiltration, and advanced oxidation processes, can produce high-quality water suitable for reuse in non-critical applications, reducing overall water demand by 30-50% in many facilities.

Zero liquid discharge systems represent the pinnacle of water conservation technology, eliminating liquid waste streams entirely through comprehensive treatment and recovery processes. These systems recover virtually all water from wastewater streams, producing solid waste that can be safely disposed of or potentially recovered for beneficial use. While the initial investment can be substantial, these systems often provide compelling economic returns through reduced water costs, eliminated discharge fees, and enhanced regulatory compliance.

Rainwater harvesting systems offer additional opportunities for water conservation, particularly in regions where rainfall patterns are favorable. Advanced rainwater collection and treatment systems can provide significant quantities of water for non-potable uses, including cooling tower makeup, equipment washing, and landscaping irrigation. These systems require careful design to ensure water quality and system reliability, but can provide substantial water savings and enhanced supply security.

Process optimization strategies can significantly reduce water consumption without requiring major equipment investments. Advanced process design approaches, including countercurrent washing systems, optimized cleaning protocols, and improved heat exchanger designs, can dramatically reduce water requirements while maintaining or improving process performance. These approaches often provide immediate benefits and serve as stepping stones toward more comprehensive sustainability initiatives.

Energy Efficiency and Renewable Integration

The energy intensity of pharmaceutical manufacturing presents both significant challenges and substantial opportunities for sustainability improvements. Pharma energy efficiency initiatives encompass a broad range of technologies and approaches, from fundamental process optimization to comprehensive facility energy management systems that integrate renewable energy sources and advanced energy storage technologies.

Modern pharmaceutical facilities increasingly incorporate comprehensive energy management systems that monitor and optimize energy consumption across all facility operations. These systems utilize advanced analytics to identify energy waste, optimize equipment operation, and predict maintenance needs that could impact energy efficiency. The integration of artificial intelligence and machine learning enables these systems to continuously improve performance and adapt to changing operational conditions.

Heat recovery and thermal integration technologies offer substantial opportunities for energy savings in pharmaceutical manufacturing. Advanced heat exchanger networks can capture waste heat from one process and utilize it in another, dramatically reducing overall energy requirements. Combined heat and power systems can provide both electricity and thermal energy with higher overall efficiency than separate generation systems, while also providing enhanced energy security and reliability.

The integration of renewable energy sources has become increasingly practical and economically attractive for pharmaceutical manufacturing facilities. Solar photovoltaic systems, wind turbines, and geothermal systems can provide clean, renewable energy while reducing operating costs and enhancing energy security. Advanced energy storage systems enable facilities to maximize the value of renewable energy by storing excess generation for use when renewable sources are not available.

Green pharma processes increasingly incorporate energy-efficient technologies and process intensification approaches that reduce energy requirements while improving process performance. Advanced reactor designs, optimized separation processes, and integrated manufacturing approaches can significantly reduce energy consumption per unit of product while often improving product quality and reducing production costs.

Waste Minimization and Circular Economy Principles

The adoption of circular economy principles in pharmaceutical manufacturing represents a fundamental shift from traditional linear production models toward closed-loop systems that minimize waste generation and maximize resource utilization. This transformation requires comprehensive redesign of manufacturing processes, supply chains, and waste management systems to create truly sustainable operations.

Green chemistry principles provide the scientific foundation for waste minimization in pharmaceutical manufacturing. These principles emphasize the design of chemical processes that reduce or eliminate hazardous materials, improve atom economy, and minimize waste generation. The implementation of green chemistry approaches often requires significant investment in research and development but can deliver substantial long-term benefits through reduced waste treatment costs, improved worker safety, and enhanced environmental performance.

Solvent recovery and recycling systems have become essential components of sustainable pharmaceutical manufacturing. Modern solvent recovery technologies can achieve very high recovery rates while maintaining solvent quality suitable for reuse in manufacturing processes. These systems not only reduce waste generation but also provide substantial cost savings through reduced solvent purchases and disposal costs.

Process intensification strategies enable more efficient manufacturing processes that generate less waste while often improving product quality and reducing production costs. These approaches include advanced reactor designs, integrated separation processes, and continuous manufacturing technologies that eliminate many of the inefficiencies associated with traditional batch processing.

Industrial symbiosis initiatives create opportunities for pharmaceutical manufacturers to collaborate with other industries to share resources and utilize waste streams. These partnerships can transform waste products from one process into valuable inputs for another, creating economic value while reducing environmental impact.

Advanced Process Technologies for Sustainability

The development and implementation of advanced process technologies specifically designed for sustainability represents a critical component of eco-friendly pharma manufacturing. These technologies often provide multiple benefits, including reduced environmental impact, improved process efficiency, enhanced product quality, and lower operating costs.

Continuous manufacturing technologies offer substantial sustainability advantages compared to traditional batch processing approaches. Continuous processes typically require smaller equipment, consume less energy per unit of product, generate less waste, and provide more consistent product quality. The smaller equipment footprint also enables more efficient facility designs with reduced construction materials and energy requirements.

Biotechnology and biocatalysis applications provide opportunities to replace traditional chemical processes with more sustainable biological approaches. Enzymatic processes often operate under milder conditions, require less energy, generate fewer byproducts, and utilize renewable feedstocks. While these technologies may require significant development investment, they often provide superior sustainability performance and can offer advantages in terms of product quality and regulatory acceptance.

Advanced separation technologies, including membrane-based separations, supercritical fluid extraction, and advanced crystallization techniques, can provide more efficient and environmentally friendly alternatives to traditional separation processes. These technologies often require less energy, generate less waste, and can provide superior product purity compared to conventional approaches.

Integrated manufacturing platforms combine multiple unit operations into single, highly efficient systems that minimize energy requirements, reduce waste generation, and improve overall process efficiency. These platforms often incorporate advanced process control systems that optimize performance across all integrated operations, delivering superior sustainability performance compared to traditional approaches.

Regulatory Framework and Compliance Strategies

The regulatory landscape governing pharmaceutical sustainability continues to evolve, with increasing emphasis on environmental performance, life cycle assessment, and comprehensive sustainability reporting. Pharmaceutical companies must navigate this complex regulatory environment while implementing sustainability initiatives that provide both environmental benefits and business value.

Environmental management systems provide structured approaches for managing environmental performance and ensuring compliance with applicable regulations. These systems typically incorporate comprehensive monitoring programs, performance metrics, and continuous improvement processes that enable companies to demonstrate environmental stewardship while identifying opportunities for further improvement.

Life cycle assessment methodologies enable comprehensive evaluation of environmental impacts throughout the entire product life cycle, from raw material extraction through product disposal. These assessments provide valuable insights into the most significant environmental impacts and help prioritize sustainability initiatives for maximum environmental benefit.

Carbon footprint reduction programs have become essential components of pharmaceutical sustainability strategies, driven by both regulatory requirements and stakeholder expectations. These programs typically incorporate comprehensive measurement of greenhouse gas emissions, identification of reduction opportunities, and implementation of mitigation strategies across all aspects of operations.

Sustainability reporting requirements increasingly demand comprehensive disclosure of environmental performance, sustainability initiatives, and progress toward sustainability goals. These reporting requirements provide important transparency but also create opportunities for companies to differentiate themselves through superior sustainability performance.

Economic Benefits and Business Case Development

The business case for sustainable pharmaceutical manufacturing has become increasingly compelling as companies recognize the economic benefits of sustainability initiatives. While some sustainability technologies require significant upfront investment, the long-term economic benefits often provide attractive returns on investment while delivering important environmental benefits.

Operating cost reductions represent the most immediate economic benefits of sustainability initiatives. Reduced energy consumption, lower water usage, decreased waste disposal costs, and improved process efficiency can provide substantial cost savings that directly impact profitability. These benefits are often sufficient to justify sustainability investments on purely economic grounds.

Risk mitigation benefits include enhanced supply chain resilience, reduced regulatory compliance risks, and improved stakeholder relationships. Companies with strong sustainability performance often enjoy enhanced reputation, improved access to capital, and reduced regulatory scrutiny, all of which provide important economic value.

Innovation opportunities frequently emerge from sustainability initiatives, as companies develop new technologies, processes, and products that provide both environmental benefits and competitive advantages. These innovations can create new revenue streams, enhance product differentiation, and strengthen market position.

Market access advantages increasingly favor companies with strong sustainability performance, as customers, regulators, and other stakeholders place greater emphasis on environmental stewardship. Companies that lead in sustainability often enjoy preferred access to markets, customers, and partnership opportunities.

Future Developments and Emerging Technologies

The future of sustainable pharmaceutical manufacturing promises continued innovation in technologies, processes, and business models that deliver superior environmental performance while maintaining or improving economic competitiveness. Emerging technologies offer new possibilities for achieving sustainability goals that may not be achievable with current approaches.

Advanced manufacturing technologies, including additive manufacturing, nanotechnology, and synthetic biology, offer new possibilities for creating more sustainable manufacturing processes. These technologies may enable production of pharmaceuticals with dramatically reduced environmental impact while potentially improving product performance and reducing costs.

Artificial intelligence and machine learning applications offer new possibilities for optimizing sustainability performance across all aspects of pharmaceutical operations. These technologies can identify optimization opportunities that may not be apparent to human operators, enable predictive maintenance that reduces energy waste, and optimize complex systems for maximum sustainability performance.

Carbon capture and utilization technologies may enable pharmaceutical manufacturers to not only reduce their carbon emissions but actually remove carbon dioxide from the atmosphere for beneficial use. These technologies are still in early development but could provide important contributions to global climate goals while creating new economic opportunities.

The transformation of pharmaceutical manufacturing toward true sustainability represents one of the most important challenges and opportunities facing the industry today. Companies that embrace comprehensive sustainability strategies will not only contribute to global environmental goals but position themselves for success in an increasingly sustainability-focused future. The convergence of environmental necessity, economic opportunity, and technological capability creates unprecedented potential for creating pharmaceutical manufacturing operations that are both environmentally sustainable and economically successful.