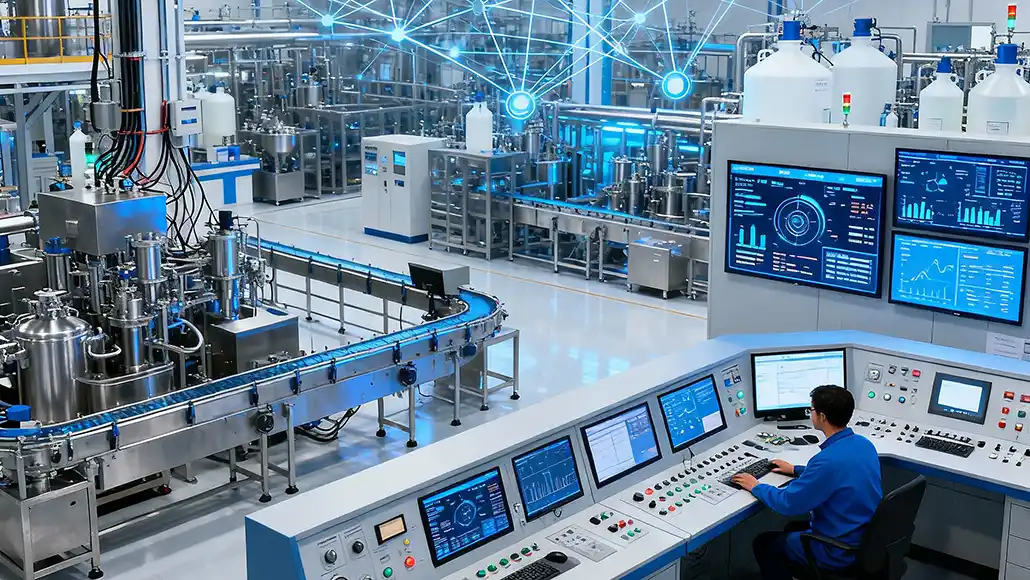

The pharmaceutical manufacturing sector stands on the precipice of a fundamental digital transformation driven by the convergence of Internet of Things technologies, edge computing, artificial intelligence, and advanced analytics platforms. IoT in pharma manufacturing represents far more than simple sensor deployment or data collection; it represents a comprehensive reimagining of how manufacturing facilities generate, process, and act upon real-time operational intelligence. Real-time monitoring capabilities enabled by sophisticated IoT networks create unprecedented visibility into manufacturing processes, equipment performance, and environmental conditions, supporting rapid corrective interventions that prevent quality deviations before they compromise product integrity.

The pharmaceutical industry’s digital transformation trajectory has accelerated dramatically, compressed by approximately five years according to recent industry assessments. Gartner’s forecasts indicate that more than 15 billion IoT devices will attach to enterprise infrastructure by 2029, while IDC predicts that edge computing applications will increase 800 percent by 2024. These expanding IoT ecosystem capabilities promise revolutionary changes for pharmaceutical manufacturing environments, particularly when combined with 5G wireless infrastructure and cloud-edge computing architectures that enable real-time analytics at the point of data generation rather than requiring transmission to centralized cloud systems.

Real-Time Process Monitoring and Quality Assurance

Sensor Networks and Data Collection Architecture

Modern pharmaceutical manufacturing facilities operate with thousands of embedded sensors monitoring critical parameters across production processes, environmental control systems, and equipment performance. These IoT networks capture real-time data regarding temperature, humidity, pressure, vibration, flow rates, and numerous other variables characterizing complex manufacturing operations. The comprehensive data collection enabled by these sensor networks creates digital representations of physical systems in near real-time, providing the foundation for advanced analytics and predictive modeling.

IoT sensor networks provide particular value in temperature-sensitive processes where precise control is essential for product quality. Real-time temperature monitoring enabled by wireless IoT devices eliminates delays inherent to traditional manual monitoring procedures while enabling immediate alerts when deviations occur. For cold chain operations where product integrity depends upon maintaining strict temperature parameters throughout storage and transportation, IoT-based monitoring systems provide continuous verification that products remain within acceptable ranges. SenseAnywhere wireless temperature mapping tools exemplify this capability, offering GMP-compliant solutions that generate real-time alerts and facilitate comprehensive audit documentation while minimizing data drift and ensuring regulatory compliance.

Process Analytical Technology Integration

Process Analytical Technology implementations enhanced by IoT connectivity provide unprecedented insight into critical manufacturing processes. Real-time monitoring of intermediate and active pharmaceutical ingredient concentrations through inline Fourier-transformed infrared and Raman spectroscopy enables immediate detection of process deviations or performance issues. Advanced partial least squares regression models processing real-time spectroscopic data achieve remarkable predictive accuracy, enabling manufacturers to verify product quality continuously throughout production rather than relying upon batch-level post-production testing.

The integration of PAT with IoT networks creates closed-loop systems where analytical data automatically triggers process adjustments or generates operator alerts when predefined thresholds are exceeded. This automated response capability dramatically reduces the latency between deviation detection and corrective action implementation, preventing quality problems from propagating through extended production campaigns. End-to-end continuous manufacturing processes leveraging real-time PAT monitoring demonstrate superior yields and consistency compared with traditional batch approaches, validating the transformative potential of IoT-enabled real-time manufacturing intelligence.

Edge Computing and Advanced Analytics

Processing Data at the Point of Generation

Edge computing technologies deployed at the manufacturing facility level enable sophisticated data analysis and decision-making without requiring data transmission to centralized cloud systems. The processing latency reduction achieved through edge computing represents a critical advantage for pharmaceutical manufacturing where immediate response to process deviations is essential. Rather than collecting data at the facility, transmitting to cloud systems, performing analysis, and transmitting corrective instructions back to facility systems—a process involving significant delays—edge computing enables analysis and response within seconds at the manufacturing location.

The computational sophistication enabled by modern edge devices has expanded dramatically, supporting deployment of machine learning algorithms, real-time optimization systems, and predictive maintenance platforms directly at pharmaceutical facilities. These edge-deployed AI systems can analyze production data, identify process anomalies, predict equipment failures, and recommend optimal control strategies based on current conditions and historical patterns. The combination of computing power and rapid response capabilities creates adaptive manufacturing systems that continuously optimize operations in real time.

Hybrid Cloud-Edge Architectures

Forward-thinking pharmaceutical organizations are implementing hybrid cloud-edge architectures that balance real-time local processing with enterprise-level analytics and data management capabilities. Critical production control functions operate locally through edge computing to ensure rapid response and reliability even during cloud connectivity interruptions. Strategic data selection transmits carefully curated information to cloud systems for enterprise analytics, trend analysis, and strategic reporting, while maintaining local operational control and response capabilities independent of cloud connectivity status.

This architectural approach addresses critical concerns regarding cybersecurity and data governance while leveraging cloud capabilities for advanced analytics and cross-facility pattern recognition. Machine learning models trained on aggregate data from multiple manufacturing sites can identify subtle patterns not apparent within individual facilities, enabling continuous improvement across entire manufacturing networks while maintaining local operational autonomy and security.

IoT Implementation Impact on Pharmaceutical Manufacturing Performance

| Metric | Baseline (Traditional) | IoT-Enabled Manufacturing | Improvement |

| Response Time to Deviations | 4-6 hours | 2-5 minutes | 95% reduction |

| Batch Cycle Time | 7-10 days | 5-7 days | 25% faster |

| Equipment Downtime | 15-20% annually | 5-8% annually | 55% reduction |

| Quality Defect Rate | 2-3% | 0.2-0.5% | 85% reduction |

| Environmental Compliance Violations | 3-5 annually | <1 annually | 90% reduction |

| Maintenance Cost | Reactive/planned | Predictive | 30% reduction |

| Regulatory Audit Findings | 4-6 per audit | 0-1 per audit | 85% improvement |

Predictive Maintenance and Equipment Optimization

Machine Learning-Powered Failure Prediction

IoT sensors deployed on critical manufacturing equipment continuously monitor operational parameters including vibration signatures, temperature profiles, energy consumption, and stress indicators that characterize machine health. Advanced machine learning algorithms analyzing these sensor streams can predict equipment failures weeks or months before they occur, enabling proactive maintenance scheduling that prevents catastrophic breakdowns while optimizing maintenance resource allocation.

Predictive maintenance implementations in pharmaceutical manufacturing environments demonstrate remarkable ROI by reducing emergency repairs, minimizing unplanned downtime, and extending equipment operating lifespans. Equipment failures in pharmaceutical facilities often result in cascading disruptions affecting production schedules, regulatory compliance, and ultimately patient access to critical medicines. Predictive maintenance approaches preventing these failures deliver benefits far exceeding direct maintenance cost savings, encompassing supply chain reliability and regulatory compliance assurance.

Automated Alerting and Maintenance Scheduling

IoT-integrated manufacturing systems automatically generate alerts when equipment parameters deviate from normal operating ranges, triggering maintenance workflows that prioritize interventions based on failure risk, equipment criticality, and production schedule constraints. Automated scheduling systems consider equipment availability, maintenance resource capacity, and production demands to optimize maintenance timing that minimizes production disruption while ensuring preventive actions occur before failures develop.

These automated systems eliminate delays inherent to manual monitoring and human decision-making, enabling facility managers to maintain optimal equipment performance while minimizing disruptions. The transparency provided by automated alerting systems supports compliance with regulatory requirements regarding equipment maintenance documentation and validation, while simultaneously improving operational efficiency.

Data Integrity and Regulatory Compliance

Comprehensive Audit Trails and Digital Documentation

IoT systems provide detailed audit trails documenting all manufacturing activities, parameter variations, corrective actions, and quality decisions with timestamps and attribution information essential for regulatory compliance. This comprehensive documentation eliminates reliance upon manual record-keeping or retrospective documentation activities, reducing opportunities for human error while providing regulatory authorities with transparent evidence of manufacturing process control.

Real-time data collection and automated documentation systems enable pharmaceutical manufacturers to demonstrate continuous regulatory compliance throughout production operations rather than inferring compliance from sampling and periodic testing. Regulatory agencies increasingly recognize that real-time monitoring and automated documentation systems provide superior evidence of manufacturing process control compared with traditional batch testing approaches.

Future Developments and Industry 4.0 Integration

Advanced Analytics and Digital Twin Integration

The convergence of IoT data streams with digital twin technologies and advanced analytics platforms is creating next-generation pharmaceutical manufacturing systems capable of predictive optimization and autonomous decision-making. Digital twins simulating facility operations based on real-time sensor data can predict how process modifications affect product quality, enabling virtual experimentation before implementing changes in actual manufacturing systems. These predictive capabilities compress optimization timelines while reducing risks associated with experimental process modifications.

Supply Chain Extension and Network Visibility

Forward-looking pharmaceutical manufacturers are extending IoT monitoring capabilities beyond individual facilities to encompass supply chains, enabling real-time visibility into raw material condition, intermediate storage environments, and product distribution channels. This expanded monitoring creates comprehensive supply chain transparency supporting rapid identification and mitigation of quality threats before products reach patients.

IoT and edge computing technologies are fundamentally transforming pharmaceutical manufacturing from reactive, experience-based operations toward predictive, data-driven systems capable of continuous optimization and autonomous decision-making. Organizations successfully implementing comprehensive IoT strategies supported by sophisticated analytics and edge computing capabilities are establishing competitive advantages through improved quality, reduced costs, and enhanced regulatory compliance that define industry leadership.