The pharmaceutical industry faces an unprecedented convergence of pressures: escalating patient demand for complex biotherapeutics, environmental imperatives to minimize waste and energy consumption, and regulatory frameworks increasingly demanding advanced contamination control and process transparency. Sustainable sterile manufacturing has emerged as the critical nexus where these pressures intersect, demanding that pharmaceutical manufacturers simultaneously achieve three challenging objectives—enhanced product quality, operational sustainability, and regulatory compliance. The global sterile injectables market, valued at approximately USD 732 billion, is projected to exceed USD 700 billion with significant growth driven by innovations in single-use systems, advanced manufacturing technologies, and closed-loop production platforms that fundamentally reimagine how vaccines and injectable therapies are produced.

The evolution toward sustainable sterile injectable manufacturing represents far more than regulatory necessity; it reflects a fundamental recognition that traditional approaches cannot scale to meet global health needs while maintaining acceptable environmental impact. Advanced manufacturing technologies—single-use systems, automated visual inspection, continuous lyophilization processes, and closed-loop platforms—are creating pathways to production systems that simultaneously achieve remarkable efficiency gains while reducing resource consumption and contamination risks. Pharmaceutical companies investing over USD 2 billion to modernize sterile injectables infrastructure recognize that sustainability and manufacturing excellence are not competing objectives but rather mutually reinforcing goals achievable through sophisticated technological innovation.

Single-Use Systems Revolution in Sterile Manufacturing

From Batch Limitations to Scalable Flexibility

Traditional sterile manufacturing relied upon dedicated stainless steel equipment designed for specific product types, requiring extensive cleaning and sterilization procedures between production runs. This approach created substantial overhead costs, extended campaign timelines, and introduced contamination risks during equipment changeover procedures. Single-use systems fundamentally transformed this paradigm by eliminating cleaning and sterilization requirements while providing unprecedented production flexibility. Instead of dedicated equipment processing a single product, single-use systems comprise sterile, pre-validated components configured specifically for each production campaign and discarded after use.

The sterile injectables manufacturing landscape has undergone remarkable transformation through single-use systems adoption. Advanced materials and manufacturing techniques now enable single-use bioreactors, filtration systems, and process equipment capable of handling large commercial volumes once considered exclusively within the domain of reusable stainless steel systems. Companies can now operate 2,000-liter single-use bioreactors at commercial scale cost-effectively, enabling scale-out strategies where multiple parallel single-use units handle production volumes previously requiring enormous centralized facilities. This architectural transformation enables distributed manufacturing networks, improved supply chain resilience, and remarkable agility in responding to market demands and product pipeline changes.

Contamination Control and Environmental Advantages

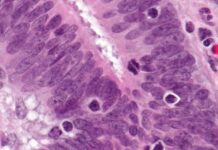

Single-use systems provide intrinsic advantages for contamination prevention that surpass capabilities of traditional approaches. Pre-sterilized, single-use components eliminate opportunities for contamination during equipment preparation, setup, and component connections. Closed-system processing enabled by single-use designs eliminates operator exposure and associated human error risks. These contamination control advantages become particularly critical for sensitive biopharmaceuticals where minimal bioburden deviations can compromise product quality or regulatory compliance.

Environmental sustainability represents an increasingly important consideration differentiating manufacturing platforms. Single-use systems simultaneously achieve water conservation by eliminating extensive cleaning procedures, energy reduction through simplified sterilization protocols, and waste reduction through optimized material utilization. Recent industry data demonstrates that single-use systems consume significantly less water and energy per unit of product compared with traditional equipment requiring extensive cleaning and sterilization. Pfizer’s investment of USD 2 billion into sterile injectables modernization specifically incorporates single-use technologies to enhance sustainability while maintaining the exceptional quality standards demanded by modern therapeutics.

Advanced Lyophilization and Stability Enhancement

Next-Generation Freeze-Drying Technologies

Lyophilization remains an essential technology for formulation stability, particularly for sensitive biopharmaceuticals including proteins, antibodies, and increasingly, nucleic acid therapeutics like mRNA and siRNA. Advanced lyophilization innovations address traditional process bottlenecks while improving product quality, reducing cycle times, and enabling more efficient facility utilization. Controlled ice nucleation techniques represent particularly significant advances, dramatically reducing variability between vials and across shelves by enabling precise control over crystalline structure formation during the freezing phase. This control reduces primary drying times for amorphous products while improving product uniformity and reducing formulation variability.

Quality by Design implementation in lyophilization development represents a paradigm shift toward science-based process optimization. Rather than discovering optimal freeze-drying conditions through extensive experimentation, QbD approaches apply fundamental principles of heat and mass transfer to create comprehensive process models predicting thermal characteristics and product behavior. This mechanistic understanding enables development of robust freeze-drying cycles that maintain product temperature reliably below critical thresholds, ensuring consistent product quality across manufacturing campaigns regardless of vial position or shelf location.

Emerging Process Innovations and Sustainability

Continuous freeze-drying represents the next frontier in lyophilization innovation, eliminating batch-to-batch transitions and enabling steady-state operation optimized for product quality and resource efficiency. Advanced automation integrated with real-time process analytical technology enables continuous monitoring of critical freeze-drying parameters including chamber pressure, condenser temperature, and product moisture, supporting immediate corrective actions when deviations occur. Microwave-assisted freeze-drying technologies further accelerate primary drying times while preserving product integrity, reducing total cycle times and facility throughput requirements.

Lyo beads—spherical freeze-dried solids engineered to provide superior flow properties and efficient freeze-drying characteristics—enable production of difficult-to-freeze products in optimized formats. These innovations collectively enable sterile manufacturing platforms capable of simultaneously achieving remarkable efficiency, superior product quality, and reduced environmental impact compared with first-generation technologies.

Single-Use vs. Traditional Sterile Manufacturing Comparison

| Factor | Traditional Stainless Steel | Single-Use Systems | Sustainability Impact |

| Setup Time | 2-4 weeks | 1-2 days | 90% faster deployment |

| Cleaning/Sterilization | 5-7 days per cycle | Eliminated | 50% water/energy reduction |

| Cross-Contamination Risk | Moderate to high | Minimal | Improved product safety |

| Capital Investment | USD 5-15 million | USD 500K-2M per campaign | Reduced upfront costs |

| Flexibility | Limited to single product | Multiple products easily | Enhanced adaptability |

| Waste Management | Extensive wastewater | Minimal processing waste | 40% plastic waste reduction target |

| Production Agility | Weeks for changeover | Days for reconfiguration | Rapid response capability |

Automated Visual Inspection and Real-Time Quality Control

Advanced Detection Technologies

Visual inspection of sterile injectable products represents one of the most critical quality assurance steps, essential for identifying particulates, cloudiness, discoloration, or other visual defects that could compromise product safety or efficacy. Automated visual inspection systems powered by artificial intelligence have revolutionized this process, providing consistent, objective evaluation of vial quality with detection capabilities exceeding human capability. Advanced imaging technologies combined with machine learning algorithms can identify sub-micron particulates, subtle color variations, and other quality deviations with remarkable accuracy while processing thousands of containers per hour.

Real-time release testing enabled by sophisticated analytical technologies eliminates traditional post-production batch testing delays. In-process monitoring combined with predictive modeling enables manufacturers to verify product quality and release batches immediately upon completion rather than weeks later. This capability becomes particularly critical for time-sensitive therapeutics where treatment delays directly impact patient outcomes, and for vaccine production where rapid response to emerging health threats demands accelerated batch release timelines.

Integration with Digital Manufacturing Systems

Advanced visual inspection systems integrate seamlessly with digital manufacturing platforms, capturing comprehensive data about product quality, production trends, and potential process issues. Machine learning algorithms analyze visual inspection data in combination with other process parameters to identify emerging quality trends and predict potential failures before they affect production. This predictive capability enables proactive process adjustments that maintain consistent quality throughout extended production campaigns.

Closed-Loop Manufacturing Platforms

Closed-loop sterile manufacturing systems represent the evolution toward fully integrated, automated production where minimal human intervention occurs during critical processing steps. These systems combine single-use components, advanced process control, real-time monitoring, and automated corrective actions into comprehensive platforms capable of producing complex sterile products with exceptional consistency. Isolator-based filling lines exemplify this advancement, maintaining isolated sterile environments throughout product transfer and packaging while eliminating operator exposure and associated contamination risks.

Regulatory agencies worldwide are actively supporting these advanced manufacturing approaches, recognizing that technological sophistication and process automation provide superior contamination control compared with traditional manual procedures. Recent revisions to EU GMP Annex 1 and emerging FDA guidance specifically acknowledge the advantages of advanced technologies and provide regulatory pathways supporting their implementation in commercial manufacturing.

Future Directions: Sustainability and Supply Resilience

The pharmaceutical industry’s commitment to sustainable sterile manufacturing reflects both regulatory imperatives and business recognition that environmental responsibility and operational excellence align perfectly. Manufacturers targeting plastic waste reduction—including Armein Pharmaceuticals’ goal to reduce plastic waste by 40% by 2025 and transition toward biodegradable packaging materials—demonstrate that sustainability initiatives enhance rather than compromise commercial viability.

Supply chain resilience emerges as an increasingly critical consideration for sustainable manufacturing systems. Distributed manufacturing networks enabled by single-use systems provide inherent advantages for geographic redundancy and rapid response to localized disruptions. The COVID-19 pandemic demonstrated that manufacturing platforms capable of flexible reconfiguration and rapid deployment prove invaluable during health emergencies when surge capacity becomes essential for meeting critical patient needs.

Sustainable sterile manufacturing represents the convergence of technological innovation, environmental responsibility, and business excellence, creating manufacturing systems that simultaneously deliver superior product quality, operational efficiency, and reduced environmental impact. Organizations that successfully implement comprehensive sustainable manufacturing platforms will establish competitive advantages through enhanced reputation, regulatory favor, and operational resilience that define industry leadership in the coming decades.