How Digital Twins Are Enabling Next-Gen Drug Packaging Lines

Revolutionizing Pharmaceutical Manufacturing Through Virtual Replication

The pharmaceutical industry has witnessed a transformative shift with the implementation of digital twins in pharma packaging lines, fundamentally changing how manufacturers approach production optimization, quality control, and operational efficiency. Digital twin technology creates dynamic virtual replicas of physical packaging systems that continuously mirror real-world operations through advanced sensors, data analytics, and machine learning algorithms. This revolutionary approach enables pharmaceutical manufacturers to predict equipment behavior, optimize production processes, and enhance quality assurance while maintaining the stringent requirements essential to pharmaceutical manufacturing.

The integration of digital twins into pharmaceutical packaging represents more than a technological upgrade—it embodies a comprehensive transformation of manufacturing philosophy that prioritizes predictive analytics, real-time optimization, and continuous improvement. These virtual systems provide unprecedented visibility into packaging operations, enabling manufacturers to identify potential issues before they impact production while optimizing performance parameters that directly affect product quality and manufacturing efficiency.

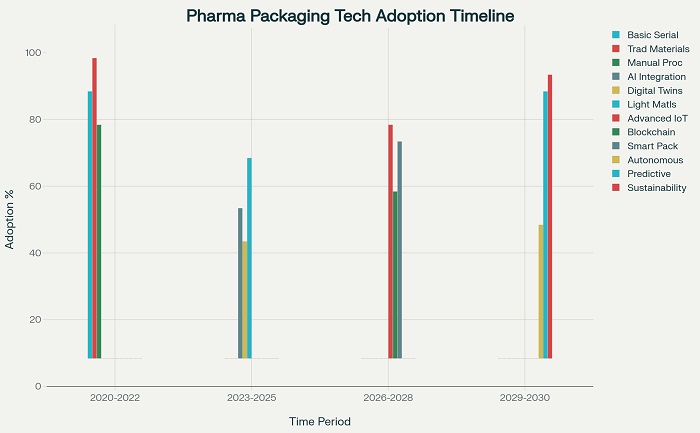

Recent industry analysis indicates that by 2025, approximately 70 percent of Global OEMs are expected to deploy digital twins for product innovation and operational performance improvements, with packaging plants among the primary adopters in the manufacturing domain. This widespread adoption reflects the compelling benefits that digital twin technology provides in complex pharmaceutical manufacturing environments where precision, reliability, and regulatory compliance are paramount considerations.

Understanding Digital Twin Technology in Pharmaceutical Context

Digital twin implementation in pharmaceutical packaging lines involves creating comprehensive virtual models that replicate every aspect of physical packaging systems, from individual machine components to complete production lines. These digital replicas continuously receive real-time data from sensors, cameras, and monitoring systems embedded throughout the packaging infrastructure, enabling precise tracking of equipment performance, environmental conditions, and product quality parameters.

The sophistication of pharmaceutical digital twins extends beyond simple monitoring to encompass predictive modeling capabilities that anticipate equipment behavior, identify potential failures, and recommend optimization strategies. Advanced machine learning algorithms analyze historical performance data, environmental conditions, and operational parameters to generate accurate predictions about future system behavior. This predictive capability enables proactive maintenance scheduling, quality issue prevention, and production optimization strategies that significantly improve overall equipment effectiveness.

Integration with existing pharmaceutical manufacturing systems requires careful consideration of regulatory requirements, data security protocols, and validation procedures. Digital twin implementations must comply with Good Manufacturing Practice (GMP) guidelines while providing comprehensive audit trails and documentation capabilities. The systems incorporate robust cybersecurity measures to protect sensitive manufacturing data while enabling seamless integration with enterprise resource planning (ERP) systems and quality management platforms.

Enhanced Quality Control and Real-Time Monitoring

Digital twins have revolutionized quality control processes in pharmaceutical packaging by providing continuous monitoring capabilities that exceed traditional inspection methods. These virtual systems track every aspect of packaging operations, from fill accuracy and seal integrity to label placement and container closure systems, creating comprehensive quality profiles for each packaged unit.

Real-time monitoring capabilities enable immediate detection of quality deviations that might otherwise go unnoticed until batch completion or final inspection. Digital twin systems continuously compare actual performance parameters against established specifications, immediately alerting operators to conditions that could affect product quality. This immediate feedback enables rapid corrective actions that prevent the production of non-conforming products while minimizing material waste and production disruptions.

Advanced vision systems integrated with digital twin platforms provide sophisticated inspection capabilities that exceed human visual inspection accuracy. These systems utilize artificial intelligence algorithms to identify subtle variations in packaging quality, including microscopic defects, color variations, and dimensional discrepancies that could indicate equipment problems or material issues. The continuous learning capabilities of these systems improve inspection accuracy over time while reducing false rejection rates.

Statistical process control integration within digital twin systems enables comprehensive trend analysis and process capability assessment. These systems continuously calculate control chart parameters, process capability indices, and statistical trends that provide insights into long-term process performance. This statistical analysis supports continuous improvement initiatives while providing documentation required for regulatory compliance and process validation activities.

Predictive Maintenance and Equipment Optimization

The implementation of digital twins has transformed maintenance strategies in pharmaceutical packaging from reactive and scheduled approaches to predictive methodologies that optimize equipment reliability while minimizing maintenance costs. Digital twin systems continuously monitor equipment condition parameters such as vibration patterns, temperature profiles, energy consumption, and operational speeds to predict when maintenance activities will be required.

Machine learning algorithms analyze equipment performance data to identify patterns that precede equipment failures or performance degradation. These predictive models enable maintenance scheduling that prevents unplanned downtime while avoiding unnecessary maintenance activities. The accuracy of predictive maintenance systems continues to improve as they accumulate operational data and refine their predictive algorithms based on actual equipment behavior.

Condition-based monitoring systems integrated with digital twins provide comprehensive equipment health assessments that guide maintenance decision-making. These systems track key performance indicators such as overall equipment effectiveness (OEE), mean time between failures (MTBF), and maintenance costs to optimize maintenance strategies. The continuous monitoring capabilities enable early detection of equipment degradation that allows for planned maintenance activities during scheduled downtime periods.

Spare parts optimization represents another significant benefit of digital twin implementation in pharmaceutical packaging. Predictive maintenance capabilities enable accurate forecasting of spare parts requirements, reducing inventory costs while ensuring critical components are available when needed. Digital twin systems track parts usage patterns, failure modes, and replacement intervals to optimize spare parts inventory levels and procurement strategies.

Process Optimization and Efficiency Enhancement

Digital twin technology enables comprehensive process optimization in pharmaceutical packaging lines by providing detailed insights into operational efficiency, bottleneck identification, and performance improvement opportunities. These virtual systems continuously analyze production data to identify optimization possibilities that enhance throughput, reduce waste, and improve overall equipment effectiveness.

Line balancing optimization represents a key application of digital twin technology in pharmaceutical packaging. These systems analyze production flow patterns, equipment utilization rates, and processing times to identify imbalances that create bottlenecks or underutilized resources. Digital twin simulations enable evaluation of different line configurations and production strategies to optimize overall line performance.

Energy consumption optimization has become increasingly important as pharmaceutical companies focus on sustainability and cost reduction initiatives. Digital twin systems monitor energy usage patterns across packaging lines, identifying opportunities for energy reduction through equipment optimization, process modifications, and scheduling adjustments. These optimizations can achieve energy consumption reductions of 15 to 25 percent while maintaining production quality and throughput requirements.

Changeover optimization represents another significant application of digital twin technology in multi-product packaging environments. These systems analyze changeover procedures, identify time-consuming activities, and recommend process improvements that reduce changeover duration. Digital twin simulations enable evaluation of different changeover strategies to minimize production losses while ensuring complete product segregation and quality compliance.

Integration with Manufacturing Execution Systems

The integration of digital twins with Manufacturing Execution Systems (MES) creates comprehensive production management platforms that enhance visibility, control, and optimization capabilities across pharmaceutical packaging operations. This integration enables seamless data flow between digital twin analytics and production management systems, creating unified platforms for operational decision-making.

Real-time production scheduling optimization becomes possible through digital twin integration with MES platforms. These systems continuously analyze production capacity, equipment availability, and order requirements to optimize production schedules that maximize throughput while meeting delivery commitments. The integration enables dynamic schedule adjustments that accommodate equipment issues, material availability, and priority changes.

Batch genealogy and traceability capabilities are enhanced through digital twin integration with MES systems. These platforms create comprehensive records of production activities, equipment conditions, and quality parameters for each batch, supporting regulatory compliance requirements and quality investigations. The integration ensures that all production data is captured and maintained in auditable formats required for pharmaceutical manufacturing.

Resource optimization across multiple packaging lines becomes achievable through integrated digital twin and MES platforms. These systems analyze resource utilization patterns, identify optimization opportunities, and recommend resource allocation strategies that maximize overall production efficiency. The integration enables coordinated optimization across multiple lines and production areas.

Regulatory Compliance and Validation Considerations

Digital twin implementation in pharmaceutical packaging must address comprehensive regulatory requirements that ensure system integrity, data accuracy, and audit trail completeness. These systems must comply with 21 CFR Part 11 requirements for electronic records and electronic signatures while providing validation documentation that demonstrates system reliability and accuracy.

Computer System Validation (CSV) procedures for digital twin systems require comprehensive testing and documentation to demonstrate that systems perform as intended and meet all regulatory requirements. Validation activities encompass installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ) testing that validates system functionality, accuracy, and reliability under actual operating conditions.

Data integrity requirements for digital twin systems encompass comprehensive controls that ensure data accuracy, completeness, and security throughout the system lifecycle. These systems implement robust access controls, audit trails, and data backup procedures that maintain data integrity while supporting regulatory compliance requirements. Regular system audits and validation reviews ensure continued compliance with evolving regulatory standards.

Change control procedures for digital twin systems require comprehensive documentation and testing of system modifications to ensure continued regulatory compliance. These procedures encompass impact assessments, testing protocols, and approval processes that validate system changes while maintaining operational continuity and regulatory compliance.

Economic Benefits and Return on Investment

The implementation of digital twin technology in pharmaceutical packaging lines provides substantial economic benefits that support compelling business cases for system deployment. These benefits encompass reduced maintenance costs, improved production efficiency, enhanced quality control, and optimized resource utilization that collectively deliver significant return on investment.

Maintenance cost reductions represent immediate and ongoing benefits of digital twin implementation. Predictive maintenance capabilities reduce unplanned downtime by up to 50 percent while extending equipment life through optimized maintenance strategies. Companies report maintenance cost savings of 20 to 30 percent within two years of digital twin deployment while achieving improved equipment reliability and availability.

Production efficiency improvements through digital twin optimization typically achieve throughput increases of 10 to 20 percent while reducing material waste and energy consumption. These efficiency gains translate directly to improved profitability through increased production capacity and reduced operating costs. The continuous optimization capabilities of digital twin systems provide ongoing benefits that compound over time.

Quality improvement benefits include reduced product rejections, decreased customer complaints, and enhanced regulatory compliance that collectively improve profitability and market reputation. Digital twin systems typically achieve quality improvement benefits that exceed implementation costs within the first year of operation while providing ongoing benefits throughout the system lifecycle.

Future Developments and Emerging Applications

The future of digital twins in pharmaceutical packaging promises continued innovation in artificial intelligence integration, advanced analytics capabilities, and expanded functionality that will further enhance manufacturing efficiency and quality control. Emerging technologies offer opportunities for enhanced predictive capabilities, autonomous optimization, and comprehensive supply chain integration.

Artificial intelligence enhancement of digital twin systems will enable more sophisticated predictive analytics, autonomous decision-making, and adaptive optimization capabilities. Machine learning algorithms will become increasingly sophisticated in their ability to predict equipment behavior, identify optimization opportunities, and recommend corrective actions that maintain optimal production performance.

Supply chain integration represents an emerging application of digital twin technology that extends virtual modeling capabilities beyond individual packaging lines to encompass entire supply chain networks. These integrated systems will enable comprehensive optimization of material flows, inventory levels, and production scheduling across multiple facilities and suppliers.

Advanced simulation capabilities will enable comprehensive evaluation of proposed equipment modifications, process changes, and facility expansions before implementation. These simulation capabilities will reduce implementation risks while optimizing investment decisions through comprehensive analysis of proposed changes and their potential impacts on production performance.

The implementation of digital twins in pharma packaging lines represents a fundamental transformation in pharmaceutical manufacturing that enhances efficiency, quality, and reliability while maintaining the stringent requirements essential to pharmaceutical production. Through continued advancement in artificial intelligence, sensor technology, and data analytics, digital twin systems will continue to provide increasingly sophisticated capabilities that optimize pharmaceutical packaging operations while supporting regulatory compliance and quality assurance objectives. This technology represents not merely an operational improvement but a strategic capability that enables pharmaceutical manufacturers to achieve competitive advantages through enhanced efficiency, quality, and reliability in their packaging operations.