Toward Zero-Waste Pharma Packaging: Trends in Recyclable and Biodegradable Materials

The Urgent Need for Sustainable Pharmaceutical Packaging Solutions

The pharmaceutical industry stands at a pivotal moment in its sustainability journey, with zero-waste pharma packaging emerging as a critical component of environmental stewardship. As global healthcare demands continue to rise, the industry faces mounting pressure to balance product safety with ecological responsibility. The shift toward recyclable and biodegradable materials represents more than an environmental mandate—it embodies a fundamental transformation in how pharmaceutical companies approach packaging design, material selection, and supply chain optimization.

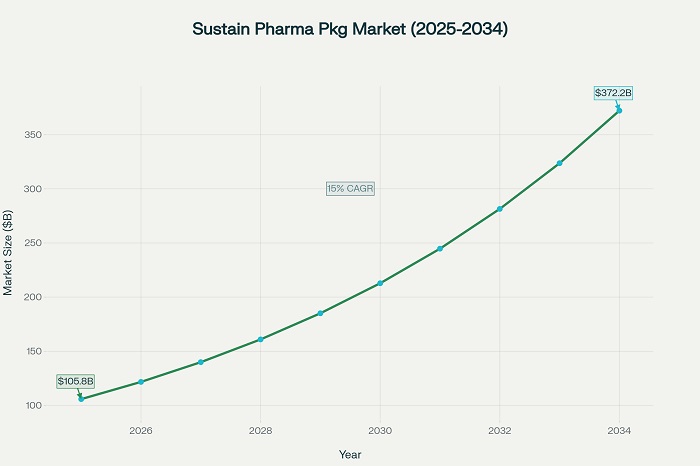

Recent market analysis reveals the sustainable pharmaceutical packaging sector has experienced unprecedented growth, expanding from USD 105.80 billion in 2025 to a projected USD 372.19 billion by 2034, representing a robust compound annual growth rate of 15 percent. This expansion reflects increasing regulatory pressures, evolving consumer expectations, and the recognition that sustainable practices can drive both environmental and economic benefits.

The concept of zero-waste pharma packaging extends beyond traditional recycling approaches, encompassing a comprehensive framework that prioritizes waste elimination throughout the entire packaging lifecycle. This holistic approach integrates biodegradable materials, circular economy principles, and innovative design strategies to minimize environmental impact while maintaining the stringent safety and efficacy standards essential to pharmaceutical applications.

Biodegradable Materials Leading the Transformation

The emergence of biodegradable packaging materials has revolutionized pharmaceutical packaging sustainability, offering viable alternatives to conventional plastic-based solutions. These materials, derived from renewable resources such as cornstarch, sugarcane, and seaweed, provide essential barrier properties while ensuring complete environmental degradation within specified timeframes.

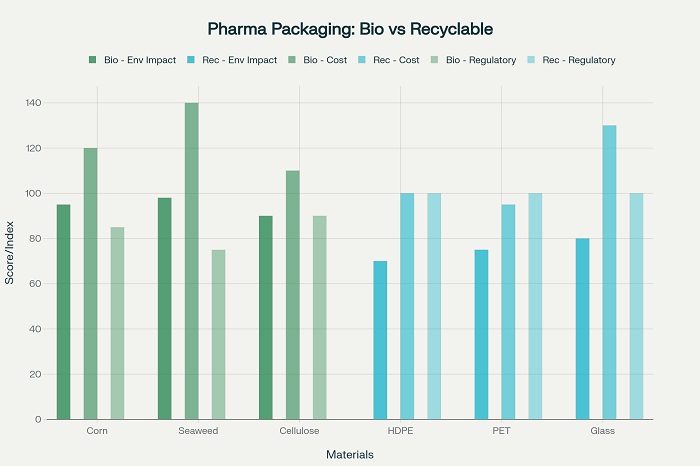

Advanced bioplastics have demonstrated remarkable progress in meeting pharmaceutical packaging requirements. Plant-based polymers now offer comparable moisture barrier properties to traditional materials while providing enhanced biodegradability. Cornstarch-derived packaging materials have shown particular promise in solid dosage form applications, breaking down into harmless organic compounds within 12 to 18 months under optimal composting conditions.

Seaweed-based packaging represents another breakthrough in sustainable pharmaceutical packaging. These marine-derived materials require minimal processing resources and offer exceptional barrier properties against oxygen and moisture. Several pharmaceutical companies have successfully implemented seaweed-based packaging for specific product lines, achieving both environmental objectives and regulatory compliance.

The development of cellulose-based packaging materials has provided additional options for pharmaceutical applications. These materials, derived from sustainably sourced wood fibers, offer excellent printability for regulatory labeling requirements while maintaining biodegradable characteristics. Advanced cellulose composites have demonstrated compatibility with various pharmaceutical formulations, ensuring product stability throughout distribution and storage.

Recyclable Packaging Systems and Circular Economy Integration

Recyclable pharmaceutical packaging has evolved beyond simple material substitution to encompass comprehensive system redesign focused on circular economy principles. Modern recyclable packaging systems prioritize material recovery, reprocessing efficiency, and closed-loop manufacturing processes that minimize waste generation and resource consumption.

Post-consumer recycled (PCR) materials have gained significant traction in pharmaceutical packaging applications. High-density polyethylene (HDPE) and polyethylene terephthalate (PET) derived from recycled sources now meet stringent pharmaceutical grade requirements while reducing reliance on virgin materials. These recycled materials undergo rigorous purification processes to ensure compliance with regulatory standards for pharmaceutical contact applications.

Monomaterial design strategies have simplified recycling processes by eliminating complex material combinations that complicate separation and reprocessing. Single-material packaging systems enable more efficient recycling streams while maintaining essential barrier properties through advanced polymer processing techniques. This approach has proven particularly effective for solid dosage form packaging, where simplified material composition supports both recyclability and product protection.

The implementation of closed-loop packaging systems has demonstrated significant environmental benefits in pharmaceutical manufacturing. These systems utilize packaging waste from manufacturing operations as feedstock for new packaging production, creating continuous material cycles that minimize waste generation. Several pharmaceutical manufacturers have achieved substantial waste reduction through closed-loop initiatives, reporting decreases of up to 40 percent in packaging-related waste streams.

Innovation in Sustainable Materials Science

Material science innovations continue to drive advances in zero-waste pharma packaging, with researchers developing novel solutions that address traditional sustainability challenges. Advanced barrier coatings derived from renewable sources now provide comparable protection to conventional synthetic materials while ensuring complete biodegradability.

Mushroom-based packaging materials, grown from mycelium networks, offer exceptional protective properties for pharmaceutical shipping applications. These materials provide superior cushioning characteristics while decomposing completely within weeks of disposal. The cultivation process requires minimal resources and can utilize agricultural waste as growth medium, creating additional environmental benefits.

Bio-based barrier films represent another significant advancement in sustainable pharmaceutical packaging. These films, produced from plant-based polymers, demonstrate excellent moisture and oxygen barrier properties essential for pharmaceutical applications. Recent developments in bio-based film technology have achieved barrier performance levels comparable to traditional synthetic materials while maintaining complete biodegradability.

The integration of natural antimicrobial agents into biodegradable packaging materials has addressed safety concerns while maintaining sustainability objectives. Plant-derived antimicrobial compounds provide essential protection against microbial contamination without compromising biodegradability. These materials have shown particular effectiveness in liquid pharmaceutical packaging applications.

Regulatory Frameworks and Compliance Considerations

The regulatory landscape for zero-waste pharma packaging continues to evolve, with agencies worldwide establishing frameworks that support sustainable practices while maintaining safety standards. The European Union’s Packaging and Packaging Waste Regulation (PPWR) exemplifies comprehensive regulatory approaches that mandate recyclability targets while accommodating pharmaceutical safety requirements.

Regulatory compliance for biodegradable pharmaceutical packaging requires extensive validation to ensure material compatibility with pharmaceutical formulations. Extractables and leachables testing has become increasingly sophisticated, with agencies requiring comprehensive analysis of potential interactions between biodegradable materials and pharmaceutical products. These testing protocols ensure that sustainable materials meet the same safety standards as conventional packaging options.

The harmonization of international standards has facilitated the adoption of sustainable packaging materials across global pharmaceutical markets. Organizations such as the Global Pharmacopoeia Committee continue to develop unified standards that support sustainable material use while maintaining consistent safety requirements across jurisdictions.

Economic Benefits and Market Drivers

The transition to zero-waste pharma packaging has demonstrated compelling economic benefits that support business case development. Reduced material costs, improved operational efficiency, and enhanced brand value contribute to positive return on investment for sustainable packaging initiatives. Companies implementing comprehensive zero-waste strategies report cost savings of 15 to 25 percent within three years of implementation.

Market demand for sustainable pharmaceutical products continues to drive investment in zero-waste packaging solutions. Consumer awareness of environmental issues has created preferences for products with sustainable packaging, influencing pharmaceutical companies to prioritize environmental considerations in packaging decisions. This market demand supports premium positioning for products with demonstrated environmental benefits.

Supply chain optimization through sustainable packaging has yielded additional economic benefits. Lightweight biodegradable materials reduce transportation costs while simplified recyclable designs improve packaging line efficiency. These operational improvements contribute to overall cost reduction while supporting environmental objectives.

Technology Integration and Digital Solutions

Digital technologies play increasingly important roles in zero-waste pharma packaging implementation, enabling precise material tracking, quality monitoring, and supply chain optimization. Internet of Things (IoT) sensors embedded in biodegradable packaging provide real-time monitoring of environmental conditions while maintaining material integrity throughout distribution.

Blockchain technology has emerged as a powerful tool for tracking sustainable packaging materials throughout their lifecycle. These systems provide transparent documentation of material sourcing, processing, and disposal, supporting certification requirements and enabling continuous improvement initiatives. Blockchain implementation has proven particularly valuable for validating the sustainability claims associated with biodegradable and recyclable materials.

Artificial intelligence applications have optimized packaging design processes, enabling the development of materials that balance sustainability objectives with performance requirements. Machine learning algorithms analyze vast datasets of material properties, environmental conditions, and pharmaceutical requirements to identify optimal packaging solutions that minimize environmental impact while ensuring product safety.

Future Outlook and Emerging Technologies

The future of zero-waste pharma packaging promises continued innovation in materials science, processing technologies, and system design. Emerging technologies such as edible packaging materials derived from food-grade polymers offer revolutionary approaches to pharmaceutical packaging that eliminate waste entirely through consumption or rapid biodegradation.

Advances in nanotechnology are enabling the development of ultra-thin barrier coatings that provide exceptional protection while minimizing material usage. These nanocoatings can be applied to biodegradable substrates to create high-performance packaging systems with minimal environmental impact.

The integration of renewable energy sources in packaging production has become increasingly important for achieving true zero-waste objectives. Solar and wind-powered manufacturing facilities reduce the carbon footprint associated with sustainable packaging production while supporting broader environmental goals.

Smart packaging technologies that provide real-time information about product condition while utilizing biodegradable materials represent the convergence of sustainability and innovation. These systems enable enhanced patient safety while minimizing environmental impact through intelligent material selection and design optimization.

The transformation toward zero-waste pharma packaging reflects the pharmaceutical industry’s commitment to environmental stewardship while maintaining the highest standards of product safety and efficacy. Through continued innovation in materials science, regulatory collaboration, and technology integration, the industry is poised to achieve significant reductions in packaging waste while supporting global health objectives. The adoption of recyclable and biodegradable materials represents not merely an environmental initiative but a strategic business imperative that aligns sustainability with operational excellence and market competitiveness.