By the year 2025, it is projected that the worldwide expenditure on pharmaceuticals would amount to around $1,742 billion, according to the most recent market studies. While this is happening, it is expected that the total amount of money spent on COVID-19 vaccines and therapies would reach around $53 billion globally in the same year.

In the pharmaceutical industry, there are two primary trends that are now impacting the market: first, there has been a noteworthy increase in the number of novel pharmaceuticals that provide significant therapeutic benefits. Second, the oral solid dose form continues to be the kind that is most often used all over the world.

Dealing with the Problem of Low Bioavailability

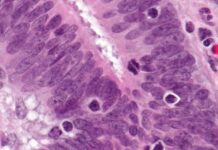

As a consequence of the innovative active pharmaceutical components being created to be extraordinarily specific to their respective biological targets, the therapeutic advantages that are achieved are ground-breaking, and the adverse effects are minimized. When it comes to producing them into oral solid dose forms, however, there are special problems that arise. One of these issues is the very powerful nature of these active compounds, which may occasionally reach up to OEB 5 levels. Other challenges include poor solubility and low oral bioavailability.

Therefore, in order to satisfy the need for these medications on a worldwide scale, contract manufacturers and developers need to be able to provide pharmaceutical customers with cutting-edge technology. The commercial production and formulation development processes cannot function without these technologies in order to properly handle the difficulties posed by the market. As a consequence of this, inventors and manufacturers are required to make use of cutting-edge technology and provide solutions for the management of exceedingly powerful active components. In order to provide greater clarification on this topic, an example from the area of cancer might be used.

Diverse Requirements for Highly Effective Active Pharmaceutical Ingredients

Over the course of the last ten years, oncology and immunomodulating treatment have become more significant as a consequence of developments in drug research. These breakthroughs have led to the creation of chemicals that are more specific to certain targets. There is a significant improvement in the risk-benefit profile of these active compounds. Because of this, extremely powerful active pharmaceutical ingredients, also known as HPAPIs, are becoming more popular and will play an essential part in the treatment of future medication conditions.

There has been a significant increase in the demand for cancer treatments in particular. At the same time, the patient groups that are being targeted are decreasing, and the number of stock keeping units (SKUs) that are being created is also decreasing. On the other hand, the process of developing and manufacturing medications that include very strong active pharmaceutical components in cancer is extremely complicated and often has to be completed within a limited amount of time. As a result of the fact that many of these novel molecular entities (NMEs) are being licensed as “breakthrough therapy” in a streamlined procedure in order to quickly fulfill the huge demand in the medical field, this urgency has arisen.

The significance of having a capable Contract Development and Manufacturing Organization (CDMO) partner who is able to speed up the process of transitioning from the development stage to the commercial production stage is highlighted by this context. In order to do this, it is necessary to not only have the ability to impart technical knowledge and inventive development experience, but also to possess the right equipment for development scale-up and ultimate high-volume manufacturing. The design of appropriate methods for the management of very powerful active substances is also required as a result of this.

Clients are able to enjoy the advantages of seamlessly transitioning from the development phase to the production phase when the same CDMO partner is responsible for both the development and manufacturing processes. The rapid introduction of new items to the market is substantially facilitated as a consequence of this, which leads to a period of time that is decreased, risk that is minimized, and cost efficiency that is boosted.